Click

on the image to download a print quality scan

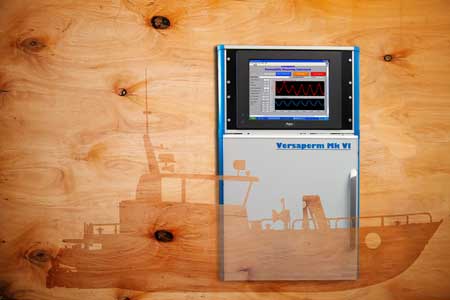

Marine plywood is widely used in the marine and boat industries due to its strength and water resistant core. However, although resistant to liquid water, water or fuel as vapour can permeate straight through it, which can condense on the other side of the panel, or even between the panel layers. This can cause very serious problems – including ply de-lamination, weakening and for safety-critical equipment such as electronics. The answer is Versaperm.

Traditionally this permeability is measured using the ASTM Method E96 – but this takes days or weeks to produce a single measurement. Versaperm's highly accurate vapour instrumental permeability equipment can reduce this down to as little as 30 minutes for some materials.

The Versaperm equipment uses modern instrumental and sensor techniques and it can measure the permeability both quickly and accurately under a wide range of environmental conditions. It can also measure the vapour permeability for fuels and other hydrocarbon vapours.

The vapour permeability of marine ply not only varies depending on the type, thickness and coating used on the material but also can be 15 - 20 times higher when wet than when measured when dry. It also varies with temperature.

Versaperm also offers a vapour permeability laboratory service for companies which only need to test samples on an irregular basis.

ENDS

* The ASTM Method E96 is based on measuring the very small change in weight of a desiccant which was placed on the far side of the marine ply to capture any moisture that passes through.

Please send any sales enquiries to

Versaperm Ltd: 10 Rawcliffe House, Howarth Road, Maidenhead, Berkshire, SL6 1AP, UK,

e.mail: info@versaperm.com Web: www.versaperm.com

UK Tel: +44 (01628) 777668

USA Tel +1 (617) 855-7477

For Further Press Information please contact:

Gerry Palmer @ the Palmer & Rose Partnership

Tel +44 (0) 1494 637499

e.mail gerry@palmer-rose.co.uk